ERP Program: Think of it as the central nervous system of your business. This comprehensive software system integrates all facets of your operations—from finance and human resources to supply chain and customer relationship management—into a single, unified platform. Imagine the efficiency gains! This deep dive explores ERP programs, demystifying their functionalities, benefits, and the crucial steps to successful implementation.

From choosing the right vendor and navigating the complexities of deployment (cloud, on-premise, or hybrid) to optimizing performance and future-proofing your system, we’ll cover it all. We’ll also tackle the potential pitfalls and offer solutions to ensure your ERP journey is smooth and rewarding. Get ready to unlock your business’s full potential!

Defining ERP Programs

Enterprise Resource Planning (ERP) software is the backbone of many modern businesses, streamlining operations and improving efficiency across various departments. It integrates all facets of a company’s operations, from planning and purchasing to manufacturing, sales, and accounting, into a single, unified system. This centralized approach fosters better communication, data visibility, and ultimately, profitability.

At its core, an ERP program acts as a central database, providing real-time access to critical information for all authorized users. This allows for informed decision-making based on accurate, up-to-the-minute data, rather than relying on disparate, potentially outdated information spread across different departments and systems.

Core Functionalities of ERP Programs

ERP systems offer a wide range of functionalities designed to automate and integrate business processes. Key functionalities include inventory management, supply chain management, order processing, financial accounting, human resource management, and customer relationship management (CRM). These modules work together seamlessly, providing a holistic view of the business. For instance, accurate inventory data from the inventory management module feeds directly into the production planning module, ensuring efficient resource allocation and preventing production delays.

Similarly, sales order data is instantly reflected in inventory levels, preventing overselling and stockouts.

ERP Modules: A Detailed Breakdown, Erp program

A typical ERP system comprises several interconnected modules, each focusing on a specific area of business operations. These modules can be tailored to fit the specific needs of a business, with some companies choosing to implement only essential modules while others opt for a more comprehensive suite. Common modules include:

- Financial Management: Handles accounting, financial reporting, budgeting, and forecasting.

- Human Capital Management (HCM): Manages employee data, payroll, benefits, and performance management.

- Supply Chain Management (SCM): Oversees procurement, inventory management, warehousing, and logistics.

- Customer Relationship Management (CRM): Manages customer interactions, sales, and marketing activities.

- Manufacturing: Plans and manages production processes, including materials requirements planning (MRP).

- Project Management: Tracks project progress, resources, and budgets.

ERP Deployment Models

Businesses have several options when it comes to deploying an ERP system. The choice depends on factors such as budget, IT infrastructure, and the company’s specific needs.

- Cloud-Based ERP: The software resides on the vendor’s servers and is accessed via the internet. This offers scalability, accessibility, and reduced upfront costs. Examples include SAP S/4HANA Cloud and Oracle Cloud ERP.

- On-Premise ERP: The software is installed and maintained on the company’s own servers. This offers greater control over data and security but requires significant upfront investment in hardware and IT expertise. Examples include many traditional SAP and Oracle deployments.

- Hybrid ERP: A combination of cloud and on-premise deployments, allowing companies to leverage the benefits of both approaches. For example, a company might host sensitive financial data on-premise while using cloud-based modules for CRM or SCM.

Open-Source vs. Proprietary ERP Solutions

The choice between open-source and proprietary ERP software involves careful consideration of several factors.

| Feature | Open-Source ERP | Proprietary ERP |

|---|---|---|

| Cost | Generally lower initial cost, but potential for higher long-term costs related to customization and support. | Higher initial cost, but potentially lower long-term costs due to included support and maintenance. |

| Customization | Highly customizable, allowing for tailoring to specific business needs. | Customization options vary, often requiring specialized expertise and potentially higher costs. |

| Support | Community-based support, with varying levels of responsiveness and expertise. | Vendor-provided support, typically with service level agreements (SLAs). |

| Scalability | Scalability can be challenging, depending on the chosen solution and the level of customization. | Generally offers better scalability, designed to handle growth and increasing data volumes. |

Benefits and Drawbacks of ERP Implementation

Implementing an Enterprise Resource Planning (ERP) system can be a game-changer for businesses, streamlining operations and boosting efficiency. However, it’s a significant undertaking with potential pitfalls. Understanding both the advantages and disadvantages is crucial for making an informed decision. This section will explore the benefits ERP offers across various business sizes, the challenges inherent in implementation, common reasons for project failure, and a checklist to guide your ERP selection process.

Advantages of ERP Implementation for Businesses of Varying Sizes

ERP systems offer a range of benefits regardless of company size. Small businesses can leverage ERP to gain better control over their finances and operations, improving visibility and reducing administrative overhead. For example, a small bakery could use an ERP system to track inventory, manage orders, and schedule employee shifts more effectively, minimizing waste and maximizing productivity. Medium-sized businesses can use ERP to improve collaboration between departments, enhance customer relationship management (CRM), and gain valuable insights from data analysis, leading to better strategic decision-making.

Large enterprises benefit from the ability to integrate disparate systems across multiple locations and subsidiaries, improving supply chain management, and facilitating global operations. Think of a multinational retail giant using an ERP system to track inventory across thousands of stores worldwide, optimizing logistics and ensuring timely product delivery. The scalability of ERP solutions makes them adaptable to the specific needs of businesses at all levels.

Challenges and Risks Associated with ERP Implementation

While the potential rewards are significant, ERP implementation presents considerable challenges. High initial investment costs, including software licensing, hardware upgrades, and implementation services, can be a major hurdle, especially for smaller businesses. The complexity of integrating different systems and migrating existing data can also lead to delays and unexpected expenses. Furthermore, employee resistance to change and the need for extensive training can impact productivity during the transition period.

Data migration errors can cause significant disruptions, potentially leading to data loss or inaccuracies. Finally, inadequate planning and a lack of skilled resources can derail the entire project, resulting in wasted time and money. For example, a poorly planned implementation could lead to system downtime, affecting sales and customer service.

Common Reasons for ERP Project Failures

ERP project failures are often attributed to a combination of factors. Poor planning and a lack of clear objectives are major contributors. Without a well-defined scope and realistic timeline, projects can easily go off-track. Inadequate user involvement and a lack of buy-in from key stakeholders can also lead to resistance and ultimately, failure. Underestimating the complexity of the implementation process and failing to allocate sufficient resources, both human and financial, are common mistakes.

Choosing the wrong ERP vendor or software solution that doesn’t fit the business’s specific needs can also result in a failed implementation. Finally, a lack of effective change management strategies can lead to employee resistance and a failure to adopt the new system. For instance, a company failing to adequately train its employees on the new system may lead to low adoption rates and ultimately project failure.

Checklist of Factors to Consider Before Choosing an ERP Program

Before selecting an ERP system, a thorough evaluation is essential. This checklist highlights key considerations:

- Clearly Defined Business Requirements: Identify your specific needs and objectives. What problems are you trying to solve with an ERP system?

- Vendor Selection: Evaluate potential vendors based on their experience, reputation, and ability to meet your requirements. Consider their track record of successful implementations.

- Software Functionality: Ensure the software aligns with your current and future business needs. Consider scalability and integration capabilities.

- Implementation Plan: Develop a detailed implementation plan that includes timelines, resources, and risk mitigation strategies.

- Budget and Resources: Accurately estimate the total cost of ownership, including software licensing, implementation, training, and ongoing maintenance.

- Data Migration Strategy: Develop a comprehensive plan for migrating your existing data to the new system, minimizing disruption and ensuring data integrity.

- Training and Support: Ensure adequate training is provided to all users, and that ongoing support is available.

- Risk Assessment: Identify potential risks and develop strategies to mitigate them.

Selecting the Right ERP Program

Choosing the right Enterprise Resource Planning (ERP) system is crucial for business success. A poorly chosen system can lead to wasted resources, integration difficulties, and ultimately, hinder growth. This section explores the key considerations in selecting an ERP program that aligns with your specific business needs and future aspirations.

ERP Vendor Comparison: SAP, Oracle, and Microsoft Dynamics

The ERP market is dominated by several major players, each offering a suite of solutions tailored to different business sizes and industries. SAP, Oracle, and Microsoft Dynamics are three prominent examples. SAP is known for its robust and comprehensive solutions, often favored by large enterprises with complex requirements. Oracle offers a similar breadth of functionality, but with a strong focus on specific industry verticals.

Microsoft Dynamics, particularly Dynamics 365, provides a more accessible and integrated solution, often preferred by smaller and medium-sized businesses due to its user-friendly interface and seamless integration with other Microsoft products. The choice depends heavily on the specific needs and resources of the organization. For example, a global manufacturing giant might opt for SAP’s extensive capabilities, while a small retail business might find Microsoft Dynamics 365 more suitable.

Key Criteria for Evaluating ERP Software

Evaluating ERP software requires a methodical approach, focusing on several critical criteria. These include functionality, scalability, cost, implementation timeline, vendor support, security, and integration capabilities. Functionality refers to the specific modules and features offered by the software, ensuring alignment with the organization’s operational requirements. Scalability refers to the system’s ability to adapt to future growth and changing business needs.

Cost encompasses not only the initial software license but also implementation, training, maintenance, and ongoing support costs. The implementation timeline considers the time required to deploy the system, minimizing disruption to business operations. Vendor support is crucial for resolving issues and ensuring the system remains up-to-date. Security features protect sensitive business data from unauthorized access. Finally, integration capabilities refer to the ease with which the ERP system can integrate with existing software and systems.

Step-by-Step Guide for ERP Selection

The ERP selection process should be a structured and iterative approach. First, define your business requirements clearly, identifying key processes and functionalities needed. Next, research and shortlist potential vendors based on your requirements and budget. Then, conduct a thorough evaluation of shortlisted vendors, including demos and presentations. Following this, request detailed proposals from the top contenders, comparing pricing, implementation timelines, and support services.

After careful consideration, select the most suitable vendor and negotiate contract terms. Finally, implement the chosen ERP system, ensuring thorough training and ongoing support. For example, a company might start by identifying its need for inventory management, then shortlist vendors offering strong inventory modules, followed by detailed evaluations and proposals before final selection and implementation.

Assessing Scalability and Adaptability of an ERP System

Assessing the scalability and adaptability of an ERP system is vital for long-term success. Scalability refers to the system’s capacity to handle increasing data volumes, user numbers, and transaction processing. Adaptability focuses on the system’s ability to accommodate changes in business processes, industry regulations, and technological advancements. This assessment should involve analyzing the system’s architecture, considering factors such as cloud-based deployment options, modular design, and API integration capabilities.

For instance, a cloud-based ERP system offers greater scalability compared to an on-premise solution, while a modular design allows for easier addition or removal of functionalities as needed. A company experiencing rapid growth should prioritize a highly scalable system to avoid future limitations.

ERP Program Implementation and Integration

Implementing an ERP system is a significant undertaking, demanding careful planning and execution. Success hinges on a phased approach, meticulous resource allocation, and a strategic data migration strategy. Ignoring these crucial elements can lead to costly delays, system instability, and ultimately, project failure. Let’s delve into the practical aspects of bringing your ERP system online.

Phases of ERP Implementation

A typical ERP implementation project unfolds in several distinct phases. These phases, while sometimes overlapping, provide a structured framework for managing the complexity of the process. Each phase requires dedicated resources and careful attention to detail to ensure a smooth transition.

- Planning and Analysis: This initial phase involves defining project goals, scope, and budget. A thorough assessment of current business processes is crucial to identify areas for improvement and tailor the ERP system accordingly. Key stakeholders are identified and their roles defined.

- System Selection and Design: Once the requirements are clear, the appropriate ERP system is selected, often involving a competitive bidding process. The system is then configured to meet the specific needs of the organization, including customizations and integrations with existing systems.

- Data Migration: This critical phase involves transferring data from legacy systems to the new ERP system. Data cleansing, validation, and transformation are crucial to ensure data accuracy and integrity in the new system. Careful planning and testing are essential to avoid data loss or corruption.

- Testing and Training: Before go-live, rigorous testing is performed to identify and resolve any bugs or inconsistencies. Comprehensive training is provided to end-users to ensure they are comfortable using the new system. This often includes both classroom and online training modules.

- Go-Live and Post-Implementation Support: The ERP system is launched, and ongoing support is provided to address any issues that may arise. Post-implementation reviews are conducted to assess the success of the project and identify areas for improvement.

Resource Requirements for ERP Rollout

Successful ERP implementation requires a blend of human, technological, and financial resources. Underestimating any of these can severely impact the project’s timeline and budget.

- Project Team: A dedicated project team, comprising IT professionals, business analysts, and end-users, is essential. The team’s expertise should cover all aspects of the implementation, from technical configuration to user training.

- Technology Infrastructure: Sufficient hardware, software, and network infrastructure are necessary to support the ERP system. This includes servers, databases, network bandwidth, and security measures.

- Financial Resources: ERP implementation is a significant investment, encompassing software licensing fees, consulting costs, hardware purchases, training expenses, and ongoing maintenance.

- Data Migration Tools: Specialized software tools are often required for efficient and accurate data migration. These tools help to cleanse, transform, and load data into the new system.

Best Practices for Data Migration

Data migration is a complex process fraught with potential pitfalls. Adopting best practices can significantly reduce the risk of errors and data loss.

A crucial step is data cleansing, which involves identifying and correcting inconsistencies, duplicates, and errors in the existing data. Data validation ensures the accuracy and completeness of the migrated data. A phased approach to data migration, starting with a pilot project, allows for testing and refinement before migrating the entire dataset. Regular backups and version control are essential to prevent data loss and enable rollback in case of errors.

ERP System Integration with Other Business Applications

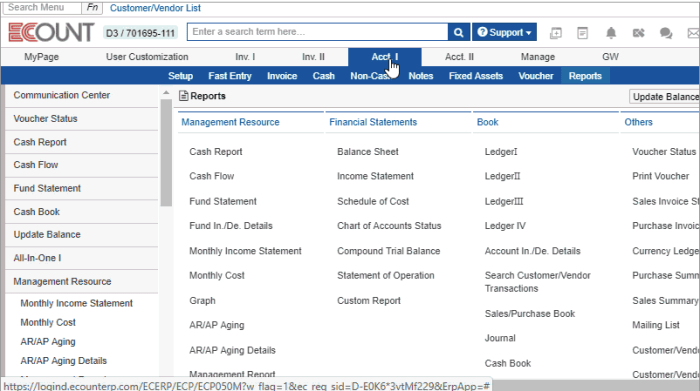

A well-integrated ERP system works seamlessly with other business applications, enhancing efficiency and data flow. This integration typically involves connecting the ERP system to CRM, supply chain management (SCM), and other relevant applications. This can be achieved through various methods, such as Application Programming Interfaces (APIs) or middleware solutions. The flowchart below illustrates a simplified example.

Imagine a flowchart: A central box labeled “ERP System” is connected by arrows to other boxes representing CRM, SCM, and a data warehouse. Each arrow is labeled with the type of data exchanged (e.g., customer data, inventory data, sales data). The data warehouse receives data from all systems for analysis and reporting.

Maintaining and Optimizing ERP Systems

Keeping your ERP system running smoothly isn’t a one-time task; it’s an ongoing commitment. Think of it like maintaining a high-performance vehicle – regular check-ups, tune-ups, and proactive maintenance are crucial to ensure peak performance and longevity. Neglecting this can lead to costly downtime, data loss, and inefficient operations. This section dives into strategies for keeping your ERP system healthy and optimized.Ongoing maintenance and support of an ERP program involves a multi-faceted approach encompassing proactive measures and reactive problem-solving.

It’s about anticipating potential issues before they arise and having a plan in place to address them swiftly and effectively when they do. This includes regular system monitoring, performance testing, and scheduled updates, all contributing to a robust and reliable system.

System Monitoring and Performance Tuning

Effective system monitoring is the cornerstone of proactive maintenance. This involves continuously tracking key performance indicators (KPIs) such as response times, resource utilization (CPU, memory, disk I/O), and error rates. Tools like application performance monitoring (APM) software provide real-time insights into system behavior, enabling early detection of potential bottlenecks or performance degradation. For instance, if database query times consistently exceed a predefined threshold, it signals a need for database optimization, perhaps through indexing or query rewriting.

Similarly, unusually high CPU usage might indicate the need for hardware upgrades or application code optimization. By identifying and addressing these issues promptly, you prevent minor problems from escalating into major disruptions.

Addressing Common ERP System Issues

ERP systems, despite their sophistication, are prone to certain common issues. Data integrity problems, for example, can arise from incorrect data entry, faulty integrations, or system errors. A robust data validation process, incorporating data cleansing and error correction routines, is crucial to maintain data accuracy. Another frequent issue is user adoption challenges. Insufficient training or poorly designed user interfaces can lead to low user satisfaction and inefficient system usage.

Addressing this requires comprehensive user training programs, regular feedback sessions, and iterative improvements to the user interface based on user feedback. Integration problems between different modules or external systems are also common. Careful planning, robust testing, and effective communication between different teams involved in the integration process are vital to ensure seamless data flow.

Regular Security Updates and Patches

Regular security updates and patches are non-negotiable for any ERP system. ERP systems often hold sensitive business data, making them prime targets for cyberattacks. Failing to apply security updates leaves the system vulnerable to exploits, potentially leading to data breaches, financial losses, and reputational damage. A well-defined patch management process, including a system for testing patches in a non-production environment before deploying them to the live system, is crucial.

This process should also incorporate a robust change management system to track and document all changes made to the system. For example, failing to patch a known vulnerability in a specific module could expose your company to ransomware attacks, resulting in significant financial losses and business disruption. A proactive approach to security updates minimizes this risk significantly.

The Future of ERP Programs

The Enterprise Resource Planning (ERP) landscape is undergoing a rapid transformation, driven by technological advancements and evolving business needs. No longer simply back-office systems, modern ERPs are becoming the central nervous system of organizations, powering everything from supply chain management to customer relationship management. This evolution is fueled by a convergence of emerging technologies that are reshaping the capabilities and functionalities of ERP systems.The integration of cutting-edge technologies is dramatically altering how businesses operate and compete.

This shift necessitates a dynamic and adaptable ERP system capable of handling the complexities of a rapidly changing global market. Understanding these emerging trends is crucial for businesses looking to leverage the full potential of ERP in the years to come.

Artificial Intelligence and Machine Learning in ERP

AI and ML are revolutionizing ERP systems, enabling predictive analytics, automated processes, and improved decision-making. Machine learning algorithms can analyze vast amounts of ERP data to identify patterns and predict future trends, allowing businesses to optimize inventory levels, anticipate customer demand, and proactively address potential supply chain disruptions. For example, an AI-powered ERP system could analyze historical sales data, weather patterns, and economic indicators to forecast demand for a particular product, enabling the company to adjust production accordingly and avoid stockouts or overstocking.

This leads to significant cost savings and improved efficiency. AI-driven chatbots are also becoming increasingly integrated into ERP systems, providing instant customer support and streamlining internal communication.

ERP Systems Adapting to the Changing Business Landscape

ERP systems are adapting to meet the demands of a constantly evolving business environment. The rise of cloud computing has led to the proliferation of cloud-based ERP solutions, offering greater flexibility, scalability, and accessibility. These cloud-based systems allow businesses to access their data and applications from anywhere, anytime, on any device, fostering collaboration and improving decision-making. Furthermore, the increasing focus on sustainability is driving the development of ERP systems with integrated sustainability modules.

These modules allow businesses to track their environmental impact, optimize resource consumption, and comply with environmental regulations. For instance, a manufacturing company could use an ERP system to monitor energy consumption in its production facilities, identify areas for improvement, and reduce its carbon footprint.

Potential Future Developments in ERP Technology

The future of ERP promises even more sophisticated capabilities. Several key developments are on the horizon:

The increasing adoption of blockchain technology within ERP systems offers significant potential for enhanced security, transparency, and traceability throughout the supply chain. Imagine a scenario where every stage of a product’s journey, from raw material sourcing to final delivery, is recorded on an immutable blockchain ledger. This would provide unparalleled visibility and accountability, reducing the risk of fraud and counterfeiting.

The integration of extended reality (XR) technologies, such as augmented and virtual reality, is poised to transform how businesses interact with their ERP systems. Imagine technicians using AR headsets to access real-time data overlays on equipment during maintenance, or sales representatives using VR to showcase products to clients remotely. These immersive experiences can significantly enhance productivity and customer engagement.

The development of more user-friendly and intuitive interfaces, leveraging technologies like natural language processing (NLP) and voice recognition, will make ERP systems more accessible and easier to use for all employees, regardless of their technical expertise. This will democratize access to crucial business information and empower employees to make data-driven decisions.

Case Studies of ERP Implementations

Understanding the practical application of ERP systems requires examining real-world examples. Successful implementations highlight the transformative potential, while unsuccessful ones illuminate crucial pitfalls to avoid. Analyzing these case studies provides valuable insights for organizations considering ERP adoption.

This section presents several case studies illustrating both the triumphs and challenges of ERP implementation across diverse industries. We’ll examine the specific hurdles encountered and how they were overcome, ultimately comparing the outcomes of successful and unsuccessful projects to offer a clearer picture of what makes an ERP implementation truly effective.

Successful ERP Implementation: Manufacturing Sector

Consider a mid-sized manufacturing company, “Precision Parts Inc.”, which implemented an SAP ERP system. Prior to implementation, they struggled with siloed data, leading to inefficient production planning and inventory management. The company faced challenges in data migration, requiring extensive data cleansing and validation. However, by engaging experienced consultants and providing thorough employee training, Precision Parts Inc. successfully integrated its various departments.

The outcome included a 20% reduction in inventory costs, a 15% improvement in on-time delivery, and a 10% increase in overall productivity. The successful implementation resulted from a clear project plan, strong leadership commitment, and comprehensive employee training.

Challenging ERP Implementation: Retail Sector

Conversely, “Retail Solutions,” a large retail chain, experienced a more difficult ERP implementation. Their attempt to implement a custom-built ERP system proved far more complex than anticipated. Poor project management, inadequate change management processes, and insufficient user training contributed to significant delays and cost overruns. The system integration proved problematic, leading to data inconsistencies and system downtime.

The project ultimately fell behind schedule and exceeded the budget by 40%. The negative impact included loss of sales, decreased employee morale, and reputational damage. This example underscores the importance of selecting the right ERP vendor and carefully managing the implementation process.

Comparison of Successful and Unsuccessful ERP Projects

The contrasting experiences of Precision Parts Inc. and Retail Solutions highlight key success factors. Successful implementations are characterized by meticulous planning, robust change management strategies, effective communication, and adequate resources. Conversely, unsuccessful implementations often stem from poor planning, unrealistic expectations, insufficient training, and inadequate project management. A key difference lies in the level of stakeholder engagement and the commitment to addressing challenges proactively.

Successful projects prioritize user adoption and ongoing support, while unsuccessful ones often fail to adequately address these crucial aspects.

Case Study Summary Table

| Industry | Company Size | ERP Vendor | Key Results |

|---|---|---|---|

| Manufacturing | Mid-sized | SAP | 20% reduction in inventory costs, 15% improvement in on-time delivery, 10% increase in productivity |

| Retail | Large | Custom-built | 40% budget overrun, significant delays, loss of sales, decreased employee morale |